Production and markets

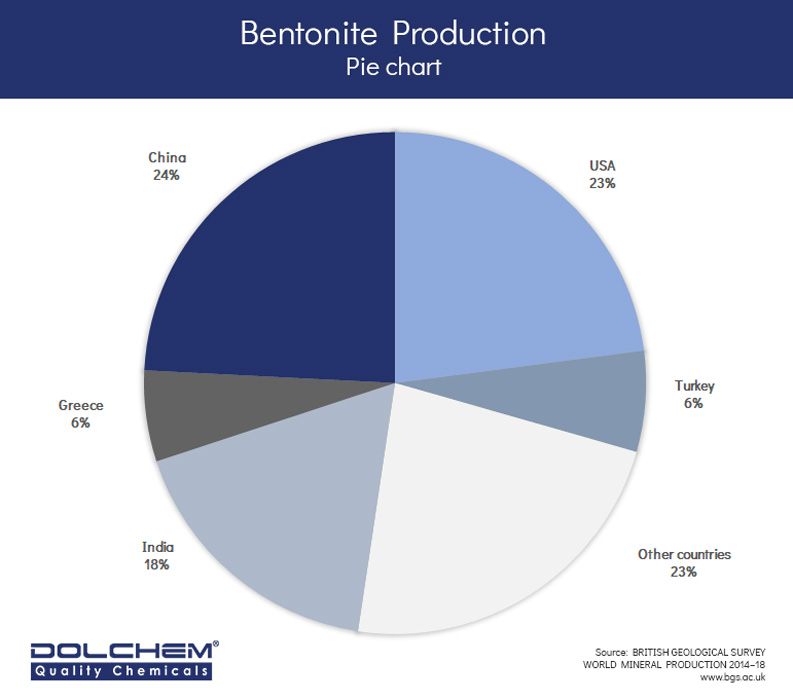

As a mineral commodity, bentonite is found in many countries and its worldwide production reached 24M tonnes in 2018 (including fuller’s earth), with China (5.6M tonnes), USA (5.3M tonnes) and India(4.1M tonnes) taking leading positions.

Bentonite types

On an industrial scale there are two majorly important types of bentonites, with distinctly different bonding properties:

- calcium bentonite, with a low degree of swelling;

- sodium bentonite, with a high degree of swelling.

While both types can be sourced naturally, it is also possible to convert calcium bentonite into sodium bentonite if needed.

Applications of Bentonite

Due to its swelling capacity as well as nontoxicity and chemical resistance, it has become an indispensable material in industrial production, especially in such applications as molding sands, drilling mud, construction, agriculture, water treatment, and many others.

Bentonite is widely used in the paint and coating industry as well, even though this is a comparatively small area of usage for this material. Bentonite is in high demand for paint production because of its properties such as strong thickening ability (often used as a thickener for solvent and water-based paints), suspending, good thixotropy, high viscosity, anti-sagging. Up to these days, organic derivatives of bentonite clay are tested and modified to discover new paint and coating applications.

Bentonite can be applied in the production of a variety of paints and coatings:

- Interior and exterior house paints

- Multi-purpose aerosols (as suspension agent) and water-based aerosol paints and coatings (eg. for marking paint)

- Decorative alkyd paints and alkyd resin coatings

- Anti-corrosive and oil sensitive paints and coatings

- Epoxy paints and none solvent epoxy paints

- Bituminous and road paints (as an emulsifier, binder, and rheological modifier)

- Chlorinated rubber paints (used in chlorinated rubber protective systems)

- Zinc-rich paints and coatings (More about Zinc Stearate applications here)

- Marine paints

- Antiseptic/antibacterial paints

In most cases, the usage of bentonite in pain and coating formulation is both a cost-saving and environmentally friendly solution.

What type of Bentonite is the best for a specific use?

That would depend on technical parameters as well, whether it is organic or inorganic bentonite, calcium or sodium bentonite. It is always a good idea to check with your supplier. It is important to know what kind of bentonite is the best for your products or use because there are tens of slightly different modifications of organic bentonite suitable for different applications. For example, DOLCHEM Bentonite 8D3 is perfect for oil-drilling applications, while DOLCHEM Bentonite BNT304 is good for industrial paint applications.

How is Bentonite used in the production of paint and coating?

There are various systems developed to apply organic bentonite in the manufacturing process. In general, it is essential to know the following:

- whether you add the dry bentonite powder directly during the production process or it has to be converted into thixotropic gel form first;

- whether there’s a need for polar activators such as ethanol, methanol, acetone or propylene carbonate.

If you are not sure what option is best for you, it is a good idea to confirm all the parameters with your supplier of Bentonite. Finding the paint and coating additives that meet your quality requirement is easier with an experienced raw materials provider like DOLCHEM®. Feel free to get in touch for more details and further discussion: