In the food additives industry, a better understanding of the customers’ needs is the key to long-term cooperation and the development of new solutions. Especially, when it comes to industrial baking, pastries or confectionery manufacturing, where the output is regular. While some manufacturers of such products as baguettes, bagels, and croissants (and many more), are certain about their choice of ingredients, others look for new formulations and applications that can bring the expected result. Usually, it is achieved easily with the help of quite common and yet efficient materials.

Why do we need food additives in bakery and pastry?

Saving time

When production volumes are high, and there’s no time to wait for the dough to strengthen naturally, some additives come in great help without worsening the quality.

Longer shelf-life (+ higher nutritional value)

We all know: manufacturing is not like cooking for your family at home. Even four days are not enough to deliver a fresh product to a final consumer, this is why there is Ascorbic Acid.

Improved texture

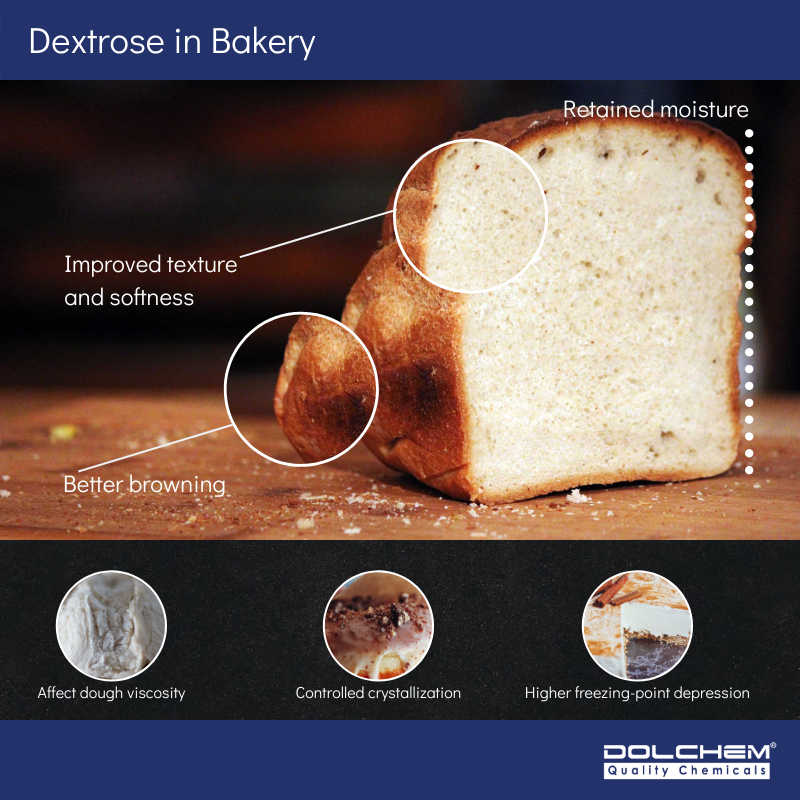

Soft, spongy, moist, light, flaky, crumbly, crusty – is just the beginning of a possible textures list for bakery or pastry products. Most of them are impossible to get using yeast only, but it becomes quite simple with Dextrose.

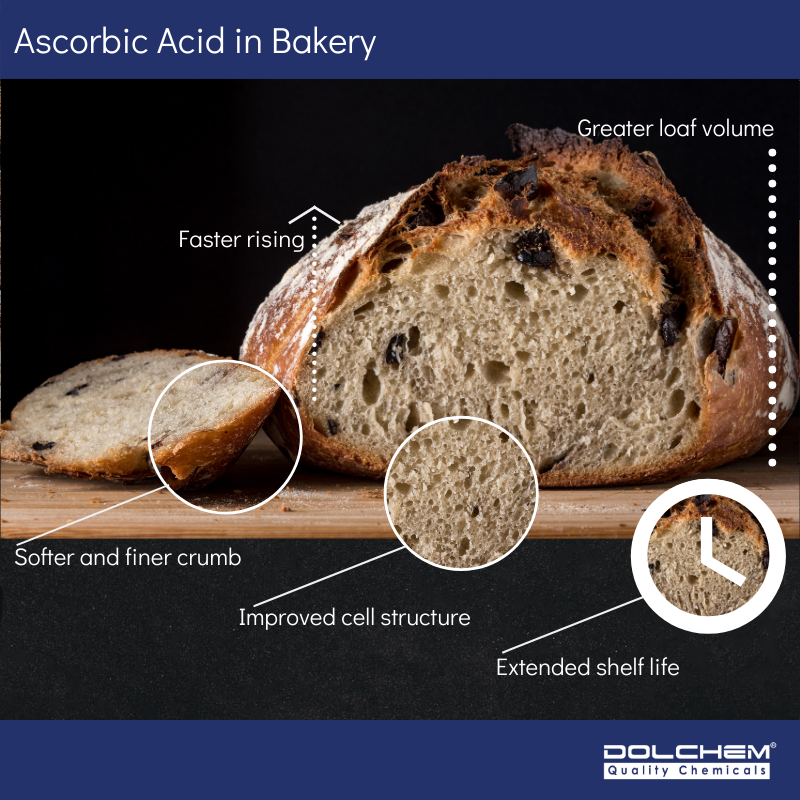

This is an essential additive, that acts as an oxidizing agent, and is considered to be a bread improver, not only extending the shelf-life of a product but increasing loaf volume by 20% (at a very small percentage in formulation) and softening the crumb as well.

As all the additives, AA is added at the stage of dough mixing, and its important to calculate the proportion carefully. Then several positive effects can be achieved:

Another advantage of using AA is meeting clean label system requirements.

Dextrose is chemically identical to glucose and can be used to replace sugar or sucrose in some food applications, including bakery and confectionery. There are two types: Dextrose Monohydrate and Dextrose Anhydrous, both purified and crystallized D-glucose, with or without molecules of water of crystallization respectively.

Dextrose is extensively used in the food industry as a humectant, sweetener, excipient, and to increase volume. In confectionery, it is often applied in the production of such products as ice cream, candies, chewing gum, toffee, fondant, etc., to improve the mouthfeel.

In addition to sweetening, dextrose stands out with a wider range of capabilities: